COR Products

Cozzolino offers a suite of products based on the COR patented engineered wood veneer. The acronym COR stands for Conserve Our Resources and highlights the “green” nature of the COR Product line. The COR Product suite consists of flat and 3-dimensional wall panels, as well as sheet goods for use in fabricating cabinetry, furniture, and other decorative millwork.

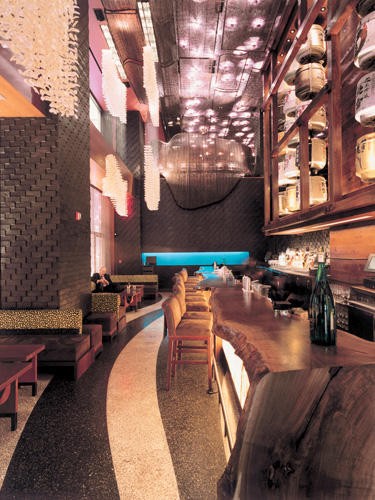

The COR veneer has a natural, organic and beautiful grain, and offers the structural advantages of shrink resistance, strength and stability not normally found in solid wood products. COR products are ideal for architects and designers looking for stunning alternatives to the classic application of wood in restaurants, corporate offices, hotels, lobby areas, stores, and residences.

Sheet Goods

COR sheet goods permit architects and designers to use the distinctive COR veneer for wall paneling, cabinetry, furniture construction, store fixtures, and other interior building applications where classic wood veneers are typically used. COR sheet goods come in standard 4x8 sheets of varying thickness (including ½”, and ¾”). COR sheet goods are available in Good-1-side and Good-2-side. Edgebanding is available for trimming.

COR sheet goods are available prefinished in one of COR’s standard colors and unfinished. COR veneer stains beautifully. Many customers choose to buy unfinished COR so that they may stain the veneer a color to match their unique needs.

Decorative Wall Panels

COR Decorative Wall Panels capitalize on COR’s inherent texture to make multi-dimensional wall panels. The wall panels are engineered with ease of installation in mind. Each pattern is delivered in a format that allows flexible configuration, simple installation, and an ingenious design in which all screws/nails can be completely hidden.

Environmentally friendly lumber

COR’s component lumber is manufactured using guidelines of solid environmental practices. Its solid engineered lumber (SEL) does not rely on old growth timber, but is harvested from readily available, fast-growing small-diameter trees that are easily renewed to provide long-term availability. This is evidenced with the use of second and third generation aspen and yellow poplar trees. Further enhancing COR’s commitment to Conserve Our Resources, COR’s component lumber uses up to 75% of every tree harvested in the manufacture of its veneer, compared to an average of 40% of the tree used in the manufacture of traditional solid sawn lumber products.

COR and their component lumber partner is committed to safely manufacturing the highest quality engineered lumber products in an environmentally responsible manner to meet their customer’s needs. COR’s structural engineered lumber is manufactured at plants which have developed and implemented log procurement policies and procedures that meet the requirements of the American Forest and Paper Association (AF&PA®) Sustainable Forestry Initiative (SFI™) or the Canadian Standards Association (CSA) Standards.

The Sustainable Forestry Initiative (SFI) is a group founded by timber and paper companies that have advanced its own set of standards. The Sustainable Forestry Initiative® Program is a comprehensive forestry management program that is a marriage of environmental responsibility and sound business practices.

In short, this means the facility that produces COR’s structural engineered lumber is part of a program whose participants plant more than 1.7 million trees every day. It is part of a program whose participants provide the wood and paper products we need, while seeking to ensure we have viable forests and wildlife for generations to come.

As described above, COR’s patented process starts with layers of solid wood. The wood strands are then laminated together with a polymerized resin. No urea-formaldehyde resins are used in the COR veneer.